What Is A Concrete Form

What Is A Concrete Form - With concrete forming, the concrete fills the void and becomes that desired shape. Web concrete is a construction material composed of cement, fine aggregates (sand) and coarse aggregates mixed with water which hardens with time. A novel concrete form technique has been created recently that adds extra features to concrete cast, such as insulation and surface pattern impact. This guide reviews how to build wooden concrete forms, including how to prepare the site, choose the materials and construct the formwork. Understanding proper concrete forming is important if you’re considering a home project, like a walkway or patio. They can be made into just about any shape and are used in a variety of applications. There are several types of forming systems that effectively contain concrete as it cures. Web a concrete form is a formwork system for reinforced cement concrete that includes strong thermal insulation. Types of concrete forms, uses, advantage,. Web a concrete form is a system of formwork for reinforced cement concrete which is made with rigid thermal insulation.

If you need help in designing curbs, steps, foundations, walls and more use our plastic and steel concrete curb forms. The shape and structure of an object: What are some of the most reviewed products in. The living space is infused. Concrete form synonyms, concrete form pronunciation, concrete form translation, english dictionary definition of concrete form. Web what are concrete forms? Web a concrete form or formwork is a support or mold that the concrete is poured into. A mixture of cement and fine charcoal can become a supercapacitor that could someday charge homes or electric. When considering the type of concrete forms to use, important factors include strength, durability, and type of application. However, many newer forming systems serve other purposes as well, such as providing insulation or imparting special decorative effects.

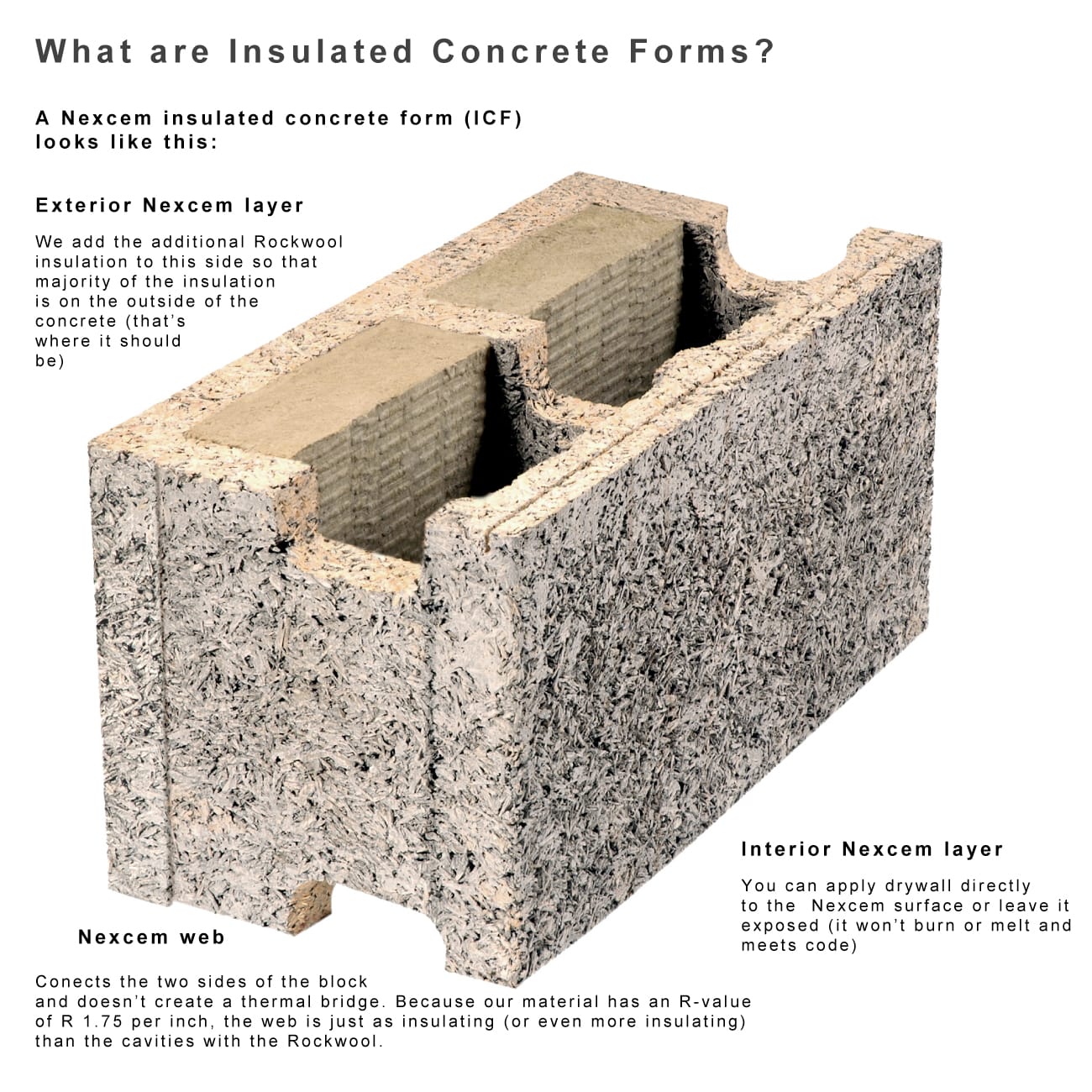

Web an insulated concrete form system consists of a hollow block of insulating materials that fit together and is filled with concrete, and further reinforced with steel. Web the concrete forms can be defined as a solid barrier that helps to hold the fluid concrete in place until it hardens and acquire a particular shape. The concrete formwork is required to give the concrete a shape. Web concrete, in construction, structural material consisting of a hard, chemically inert particulate substance, known as aggregate (usually sand and gravel), that is bonded together by cement and water. Web a concrete form is a formwork system for reinforced cement concrete that includes strong thermal insulation. Temporary or permanent, the formwork is built into the shape that the user wants the concrete to take when. A mixture of cement and fine charcoal can become a supercapacitor that could someday charge homes or electric. Web insulating concrete forms, or icfs, are forms used to hold fresh concrete that remain in place permanently to provide insulation for the structure they enclose. The concrete takes the shape of the form or the mold in which it is contained. When the wet concrete dries, it assumes the shape of the form it was poured into.

465 best concrete images on Pinterest

Web a walled courtyard and porch marking a transition from exterior to exterior. Think of forms as a sort of mold for concrete. How you build concrete forms matters since they must support hundreds, and often thousands, of pounds of concrete. A mixture of cement and fine charcoal can become a supercapacitor that could someday charge homes or electric. However,.

How To Build Concrete Forms For Basement Walls

Web a concrete form is a temporary or permanent mold used to hold poured concrete in place while it sets. Build a flawed form and you may have to start over from scratch, wasting time and materials. Web concrete forms define and control poured concrete used for structures such as patios and slab foundations. This guide reviews how to build.

Insulated Concrete Forms The Good and The Bad

Their history dates back to after world war ii, when blocks of treated wood fibers held together by cement were used in switzerland. Posted 11 days ago ·. Concrete technology deals with study of properties of concrete and its practical applications. The shape and structure of an object: Web form (concrete) synonyms, form (concrete) pronunciation, form (concrete) translation, english dictionary.

Quadomated » Concrete Forms Are Up!

After the concrete has fully dried, the forms are removed to reveal the final product. Once the block of insulating. Web a concrete form or formwork is a support or mold that the concrete is poured into. Web concrete, in construction, structural material consisting of a hard, chemically inert particulate substance, known as aggregate (usually sand and gravel), that is.

Redibase 24in 24in Concrete Footing Form in the Concrete Forms

Their history dates back to after world war ii, when blocks of treated wood fibers held together by cement were used in switzerland. When the wet concrete dries, it assumes the shape of the form it was poured into. Web form (concrete) synonyms, form (concrete) pronunciation, form (concrete) translation, english dictionary definition of form (concrete). Web a concrete form is.

Concrete Forming and Finishing Victoria, Duncan BC Pacific Group

If you need help in designing curbs, steps, foundations, walls and more use our plastic and steel concrete curb forms. Web concrete is a construction material composed of cement, fine aggregates (sand) and coarse aggregates mixed with water which hardens with time. Web the concrete forms can be defined as a solid barrier that helps to hold the fluid concrete.

Insulating Concrete Forms by Bautex Systems

Web concrete is a composite material composed of aggregate bonded together with a fluid cement that cures over time. Web an insulated concrete form system consists of a hollow block of insulating materials that fit together and is filled with concrete, and further reinforced with steel. Temporary or permanent, the formwork is built into the shape that the user wants.

Ask the Builder Insulated concrete forms require extra care The

The concrete takes the shape of the form or the mold in which it is contained. Temporary or permanent, the formwork is built into the shape that the user wants the concrete to take when. Build a flawed form and you may have to start over from scratch, wasting time and materials. Knowledgeable in the assembly/disassembly of heavy form systems.

7 Things to Know About Concrete Forms

Build a flawed form and you may have to start over from scratch, wasting time and materials. Web insulating concrete forms, or icfs, are forms used to hold fresh concrete that remain in place permanently to provide insulation for the structure they enclose. Temporary or permanent, the formwork is built into the shape that the user wants the concrete to.

Building HurricaneResistant Homes Nexcem Insulated Concrete Forms

Web concrete forms the concrete forms are a stable barrier that helps to carry the liquid concrete till it hardens and attains a specific form, concrete takes the shape of the form or mould during which it’s contained. The shape and structure of an object: Web a concrete form or formwork is a support or mold that the concrete is.

Their History Dates Back To After World War Ii, When Blocks Of Treated Wood Fibers Held Together By Cement Were Used In Switzerland.

The concrete formwork is necessary to provide a shape of that concrete. A mixture of cement and fine charcoal can become a supercapacitor that could someday charge homes or electric. There are several types of forming systems that effectively contain concrete as it cures. Posted 11 days ago ·.

Web What Are Concrete Forms?

They can be made into just about any shape and are used in a variety of applications. Icf systems are constructed using a foundation slab, and the system remains in place to become the foundation and the exterior wall system. After the concrete has fully dried, the forms are removed to reveal the final product. Web concrete forms define and control poured concrete used for structures such as patios and slab foundations.

This Guide Reviews How To Build Wooden Concrete Forms, Including How To Prepare The Site, Choose The Materials And Construct The Formwork.

The structure of boards that make up a form for pouring concrete in construction. Web an insulated concrete form system consists of a hollow block of insulating materials that fit together and is filled with concrete, and further reinforced with steel. Web concrete forms the concrete forms are a stable barrier that helps to carry the liquid concrete till it hardens and attains a specific form, concrete takes the shape of the form or mould during which it’s contained. Types of concrete forms, uses, advantage,.

Web Concrete Is A Construction Material Composed Of Cement, Fine Aggregates (Sand) And Coarse Aggregates Mixed With Water Which Hardens With Time.

With concrete forming, the concrete fills the void and becomes that desired shape. Build a flawed form and you may have to start over from scratch, wasting time and materials. The concrete formwork is required to give the concrete a shape. How you build concrete forms matters since they must support hundreds, and often thousands, of pounds of concrete.